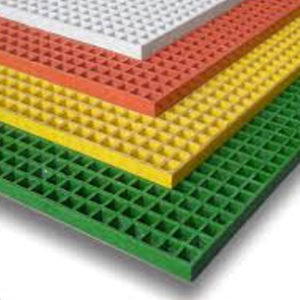

Description

50% E glass reinforcement. The pultruded load bar will be of high strength I-Beam design. All loading members shall be mechanically locked to each other via two spacing bars and central locking rod. Where anti-skid is required, a tough epoxy-quartz coating is applied to the surface of all loading members.

FEATURE BENEFITS & CHARACTERISTICS

Chemical and Corrosion Resistance The use of premium grade resins containing UV inhibitors and an outer reinforcing continuous strand mat topped by a non glass surfacing tissue, optimum protection against corrosion and weathering can be achieved. It resists a wide range of aggressive acids, salts, alkalis and other chemical environments which can have disastrous effect on metallic grating systems.

LIGHTWEIGHT AND MANAGEABLE

The pultruded fibreglass used in the gratiy has a specific gravity of one-fourth that of steel and two-thirds that of aluminium which considerably simplifies installation and handling. Unlike metallic grating, Fiber Glass grating can be easily cut on site using only hand tools.

TRANSPARENT TO RADIO FREQUENCIES

Fibreglass composites do not interfere with electromagnetic and radio frequency transmissions. Pultruded grating can be safely applied in towers and other structures used in the transmission of such signals.

NON CONDUCTIVE

Pultruded Grating can be used safely in electrical work areas. Special support conditions to prevent electrolytic corrosion are not required.

STABLE

Unlike many other fibreglass systems, the use of a double mechanical lock system to locate and space the load bars makes Grating a permanently stable panel.

NON-SKID SURFACE

Grating has a tough, quartz epoxy finish that will ensure the maximum in skid resistance and safety even in wet environments.

COST PERFORMANCE

Very favourable results have been demonstrated with the materials emphasising low installation costs and long service life with minimum maintenance. FRP Grating is designed using high strength to weight ratio pultruded structural composite profiles.

DIMENSIONS

Standard panel sizes are nominal 914mm (36 in) or 1219mm (48 in) wide by 3048mm (120 in) span. Other sizes are available to order to a maximum of 1219 mm (48 in) wide by 6096mm (240 in) span. Panel weight must be considered when ordering large panels. Special shape panels can be cut from standard width stock panels.

STANDARD GRATING

Made with premium grade isophthalic polyester resin yielding excellent chemical resistance with high physical properties.

FIRE RETARDANT GRATING

Also made with isophthalic polyester vinylester resin but with built-in fire retardant additives. Complies with ASTM E-84 and the self extinguishing requirements of ASTM D-635 and UL 94V-0.

COLOUR

Standard and fire retardant Safetread is made in Safety Yellow. Other colours can be made to order.

DESIGN

FRP grating is engineered to meet the requirements of Australian Standard AS1657-1992. An exception is Series 600 Type 600 which exceeds the open area requirement of the standard.