Description

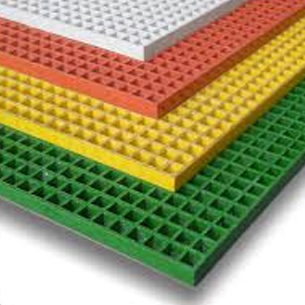

SPI moulded grating

provides an efficient and cost effective solution for all flooring, walkways and decking areas requiring long term performance in very aggressive and corrosive environments.

Constructed from glass reinforced thermoset resins, SPI moulded grating is an excellent choice to replace conventional steel and aluminium flooring systems in such environments.![]()

CHEMICAL AND CORROSION RESISTANCE

SPI moulded fibreglass grating is manufactured using high strength fibreglass rovings and a range of premium grade thermosetting resins.

HIGH STRENGTH TO WEIGHT RATIO

The use of high strength E-glass roving reinforcement, moulded to form a square mesh grating panel, produces a strong flooring system suitable for safe pedestrian traffic on a wide range of spans.

LIGHT WEIGHT AND MANAGEABLE

The composite used in the construction of SPI moulded grating has a specific gravity one-fourth that of steel and two-thirds that of aluminium which considerably simplifies installation and handling.

NON-CONDUCTIVE

SPI moulded grating can be safely used in electrical work areas. Special support conditions to prevent electrolytic corrosion are not required.

IMPACT RESISTANT

Having a square mesh and a continuous woven roving reinforcement pattern assists in providing a grating panel with high impact resistance. Repeated loads can be applied with little or no permanent deformation.

STABLE

Panels of moulded grating are inherently stable due to their square mesh construction.

NON SKID SURFACE

Standard moulded grating panels have a concave profile on the upper surface for skid resistance. Grit surfaces are also available on request and this tough quartz finish will ensure the maximum in skid resistance and safety even in wet environments.

NON SPARKING

Impact on metallic grating by metallic objects can create sparks of sufficient energy to ignite gases. SPI moulded grating installed in such dangerous areas will not create sparks when impacted with metallic or other objects.

TRANSPARENT TO Radio Frequency TRANSMISSION

Fibreglass does not cause electromagnetic interference and is transparent to radio frequency transmissions.

COST PERFORMANCE

Very favourable results can be demonstrated with SPI moulded grating with emphasis on low installation costs, long service life and minimum maintenance.

DIMENSIONS

Standard panel sizes are nominal 915mm x 3050mm (3ft x 10ft), 1220mm x 2440mm (4ft x 8ft), 1220mm x 3050mm (4ft x 10ft) and 1220mm x 3660mm (4ft x 12ft). Special shape panels can be cut from standard width stock panels. Panel weight should be considered when ordering large panels.

DESIGN

SPI moulded grating is engineered to meet the requirements of Australian Standard AS1657-1992.

STAIR TREADS

Constructed from the same square mesh grating panel with a nosing edge finished with a quartz anti-slip coating coloured to match the remainder of the panel.

SPECIFICATION

Grating panels shall be of square or rectangular mesh in 25, 38, or 51mm (1 , 1½ or 2 ) thickness. Grating shall be constructed using E-glass roving reinforcement with a matrix of either Orthopthalic Polyester, Isophthalic Polyester or Vinyl Ester resin and where necessary shall comply with the fire retardancy requirement of ASTM E-84.

The grating shall be of one piece construction with all upper load bearing surfaces in the same plane.

Upper walking surface can be concave or gritted with quartz, bonded with a tough epoxy.

Colours can be green, grey, orange or yellow.

APPLICATIONS

SPI moulded grating is designed for use in walkways, platforms and other flooring applications in these wide range of industries.

| Oil and Gas | Environmental Control |

| Industrial | Pulp and Paper |

| Food Processing | Breweries |

| Water Treatment | Chemical |

| Marine | Plating |

| Mining | Electrical |

| Mineral Processing | Telecommunications |

| Power Generation |