Description

Cage hoops and brackets shall be produced by the open molded hand lay-up method.

All structural shapes shall be composed of fiberglass reinforcement and resin.![]()

Fiberglass reinforcement shall be a combination of continuous roving, continuous strand mat, bi-directional roving mat and surfacing veil in sufficient quantities as needed by the application and/or physical properties required.

Resins shall be {Isophthalic Polyester or Vinyl Ester} with chemical formulation necessary to provide the corrosion resistance, strength and other physical properties as required.

All finished surfaces of FRP items and fabrications shall be smooth, resin-rich, free of voids and without dry spots, cracks, crazes or un-reinforced areas. All glass fibers shall be well covered with resin to protect against their exposure due to wear or weathering .

All pultruded ladder components shall be further protected from ultraviolet attack (integral UV inhibitors in the resin) a synthetic surfacing veil to help produce a resin rich surface.

All FRP products shall have a tested flame spread rating of 25 or less per ASTM E-84.

The ladder side rail shall be 1-3/4″ square tube with wall thickness of 1/4″ or greater. The rungs shall be 1-1/4″ diameter pultruded structural shapes, continuously fluted to provide a non-slip surface. Rungs that are gritted as a secondary operation shall not be permitted. Ladder wall and floor mount shall be fabricated from pultruded angles, 3/8″ minimum thickness.

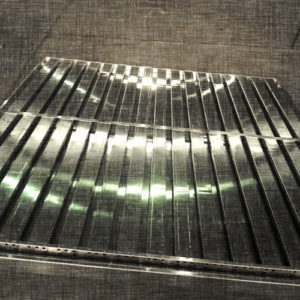

The ladder cage vertical bars shall be 1.5″ wide by 5/8″ pultruded shapes to offer protection to workers from exposed hardware. Cage hoops and cage brackets shall be manufactured by the open mold hand lay-up process. All cage hoops shall be 3″ wide by 1/4″ thick minimum.

Type 316 stainless steel bolts shall be provided for attaching ladder cage vertical bars to hoops, ladder hoops to brackets, ladder cage brackets to the ladder, and wall brackets to the ladder.

All rungs shall be both mechanically attached to the ladder with stainless steel rivets and chemically bonded with epoxy. All ladder and cage components are to be integrally pigmented yellow.

The Ladder Systems meet or exceed OSHA requirements and building code for safety and design.