Description

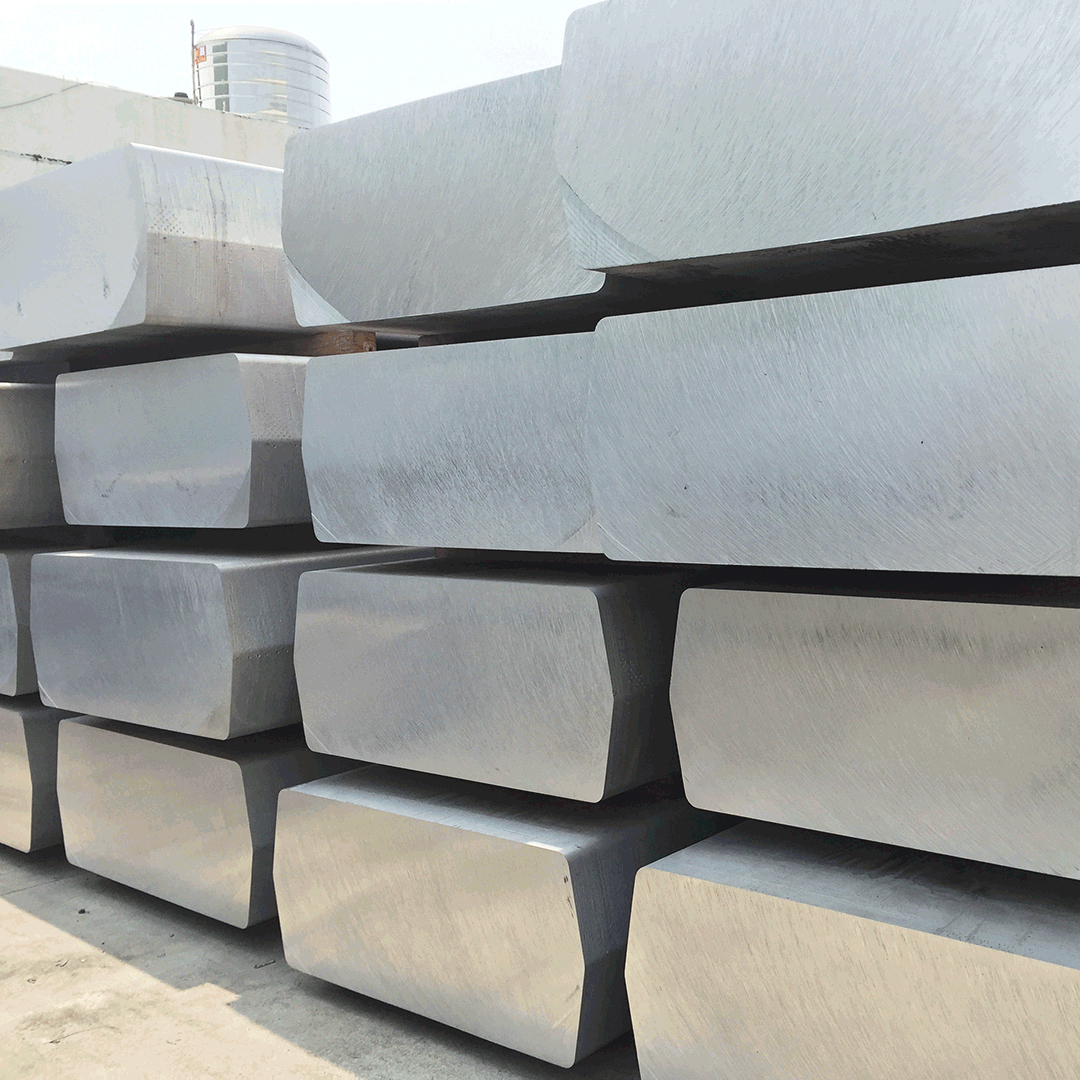

The production process for rolling slabs is subject to the same quality, safety and environmentally certified standards as the rest of Alba’s portfolio of products. This is done to ensure consistent product quality for subsequent rolling into a range of semi-fabricated products. The total annual production capacity of our rolling slabs currently stands at approximately 140,000 metric tonnes per annum.

Features:

It takes considerable precision to achieve the superior quality of rolling slabs that we produce. We start by creating a range of aluminium alloys. These include non-heat-treatable alloys in the Aluminium Association (AA) of USA in the AA1000, 3000, 5000 and 8000 aluminium alloy series. Once we’ve got the exact alloy composition, we manufacture rolling slabs using sophisticated direct chill casting machines using the latest metal level control technology and Wagstaff moulds. The metal cleanliness is ensured by the application of inline degassing and filtration equipment like ACD, ceramic foam filtration, TKR cartridge filters considered to be the best in the aluminium industry. The slabs are supplied to a specific standard on dimensional tolerance, surface finish requirement and metallurgical characteristics to ensure complete customer satisfaction.

Applications:

Rolling slabs are suitable for finished products such as ultra light gauge foils as well as for cookware foil used for food wrapping. In lithographic applications, they are used in producing offset printing plates, and are also used in the packaging industry, transport and aviation industries, construction and general engineering applications like panelling, flooring and roofing among others.